Crane Systems

Tailored Crane System Solutions Across Tennessee

Discover Innovative Crane Systems for Unmatched Lifting Solutions

Elevate your operations with our expert crane systems designed to enhance efficiency and safety. At The System Group, Inc., we understand that the right crane systems can make all the difference in streamlining your processes. Our dedicated team is here to provide tailored solutions that meet your unique needs and challenges. Serving the Tennessee area, we are committed to bridging the gap between your business demands and innovative crane technology. Let us help you lift your productivity to new heights today. Reach out to us for a consultation and see how our crane systems can transform your workspace.

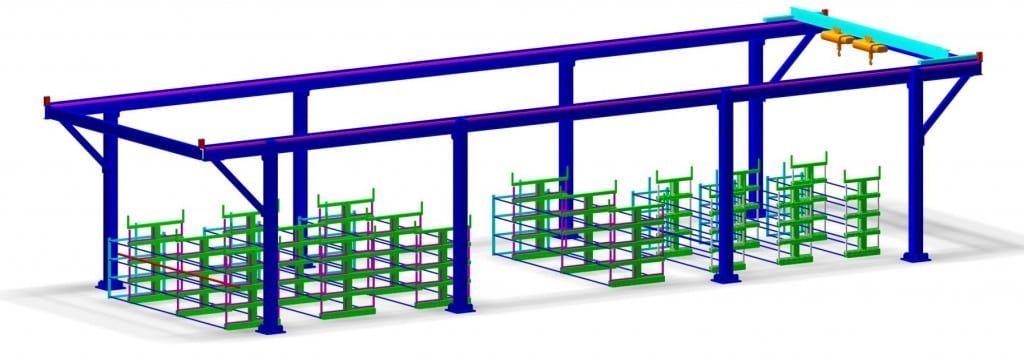

Long Part Raw Materials Staging & Picking Crane Cell

The provided crane and roll-out cantilever rack system is designed to assist associates in picking steel rod, tube, or structural components for delivery to a neighboring fabrication department.

The combined crane and roll-out cantilever rack system provides direct access to every product being stored and virtually eliminates double and triple load handling to access any specific raw material.

In similar applications, productivity and material access are significantly enhanced through the integration of well-designed crane systems .

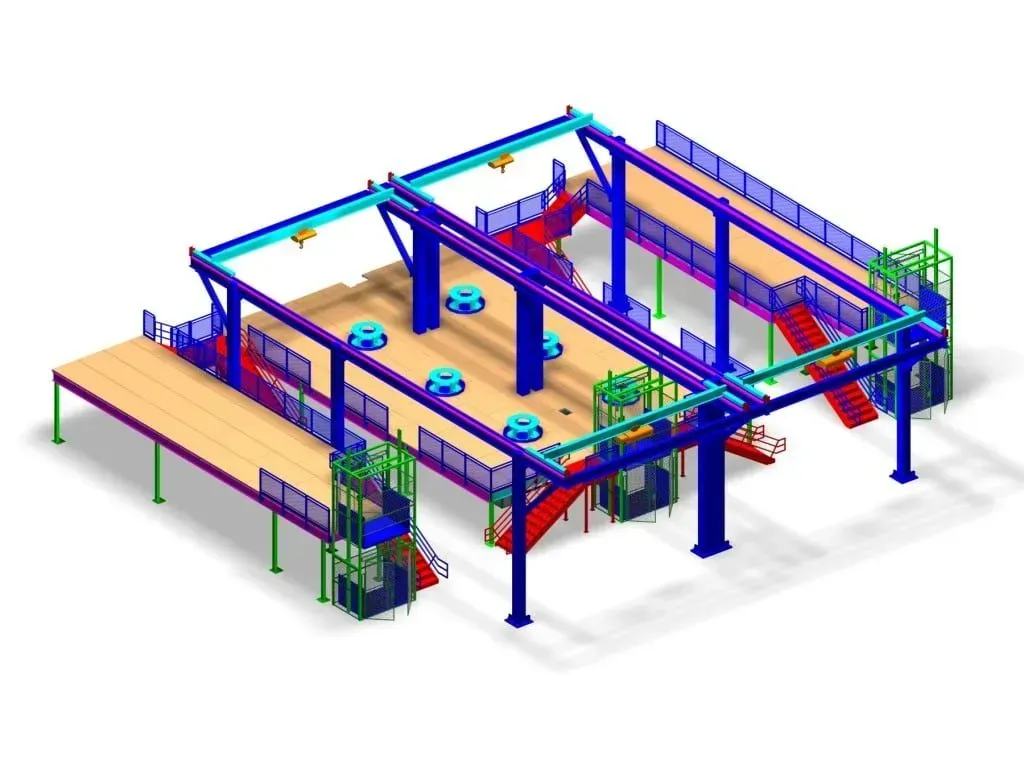

Large Product Disassembly, Repair & Rebuild System

The customer wanted to improve the department's production levels and the associates' ergonomic environment. The crane-based disassembly, repair, and rebuild system for jet engine products substantially improved productivity levels as well as associate ergonomics.

The system is an integration of radio-controlled overhead cranes, free-standing mezzanines, material lifts for parts delivery to and from the mezzanines, and six customized scissor lifts for supporting the jet engine product during disassembly and reassembly. Such improvements are often made possible by the precision and control offered by advanced crane systems

.

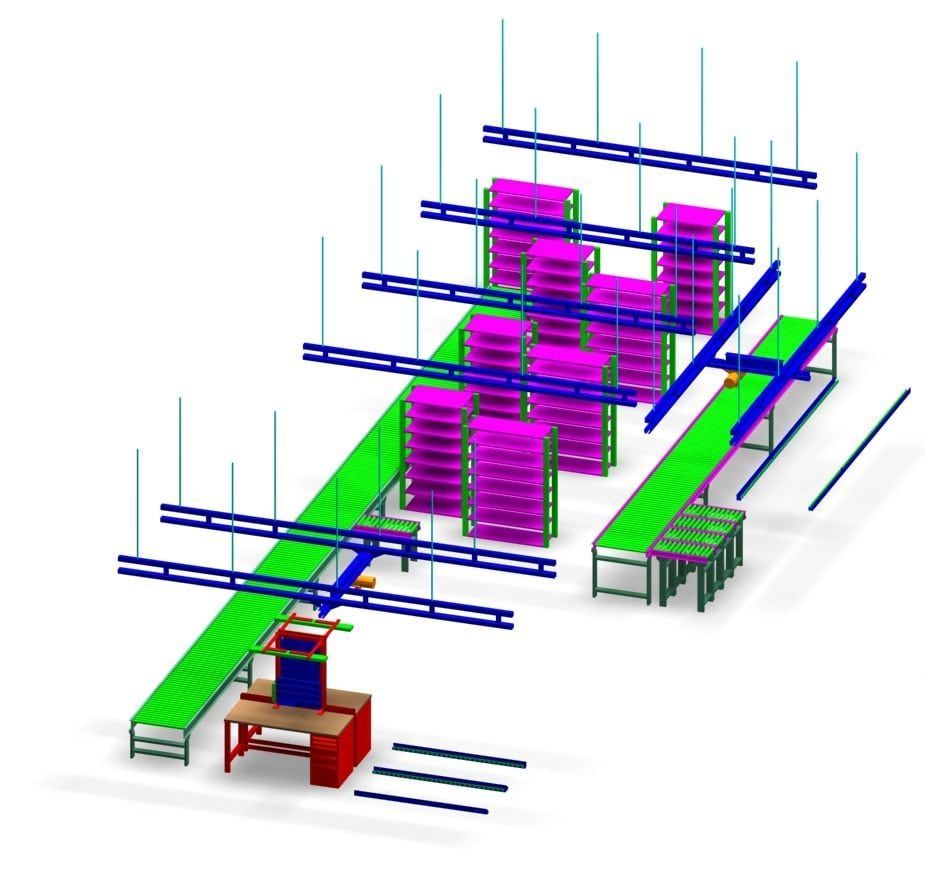

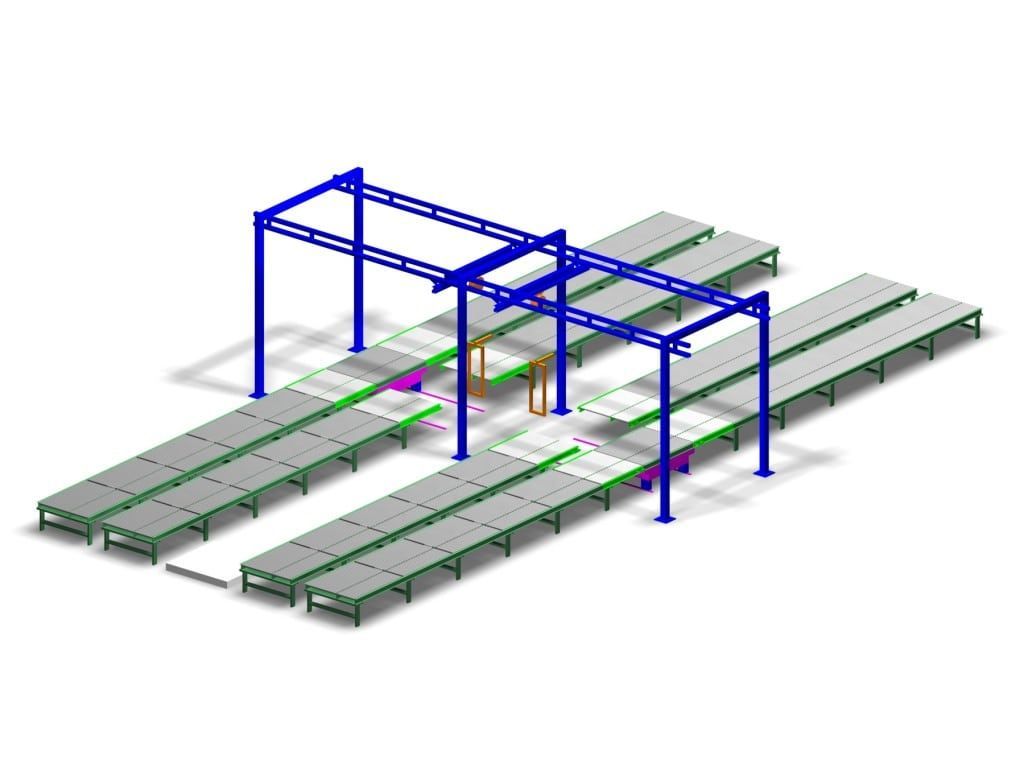

Heavy Component Assembly and Packaging Cell

A flexible conveyor-based assembly system for heavy automotive drive line components with multiple work stations assembling the units in a single piece flow process. A secondary line, to the right of the assembly line, kits the custom units into retail packaging for shipment.

The system provides better associate ergonomics with reduced lifting requirements, resulting in higher productivity per associate. Equipment designed, provided, and installed includes: zero-pressure accumulating conveyors, gravity conveyors, assembly work stations, Gorbel light bridge cranes and monorails, and purchased part shelving per assembly station. Efficiency in material handling and operator safety are both enhanced when facilities are supported by integrated crane systems .

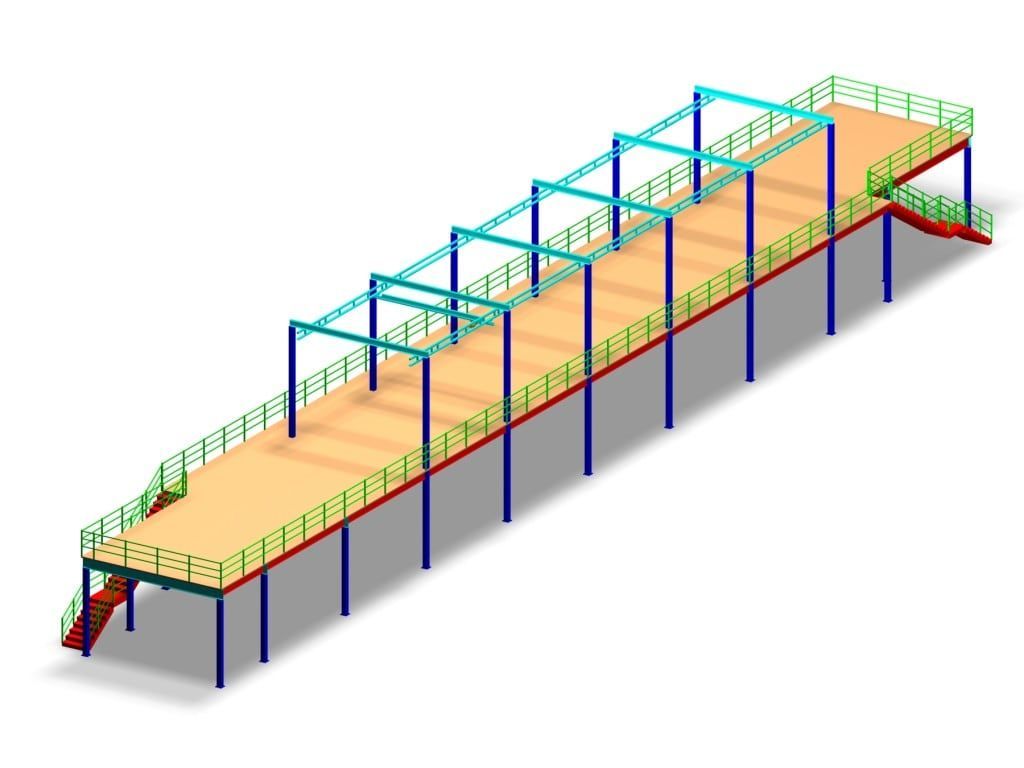

High Capacity Free Standing Mezzanine with Integral Crane System

The free-standing mezzanine with the mezzanine column-supported overhead bridge crane provides substantial additional square footage for raw material storage and delivery to an injection molding process at ground level.

The crane system allows access to any unit load of pelletized plastic materials under its travel path. This reduces the number of touches per unit load handled, resulting in lower indirect labor costs. Additional handling efficiencies are achieved in facilities like this by utilizing adaptable crane systems for vertical and horizontal movement.

Finished Goods Inspection and Repack Cell

The customer wanted a gravity conveyor-based system for product repacking of finished goods from internal captive pallets to pallets required by the various automotive end customers. The provided dual work station custom gravity flow conveyor cell with a dual overhead crane based lift assist system allowed for 100% product inspection & repalletizing with a minimum of ergonomic stress on the associates doing the work.

Ergonomic and throughput gains like these are frequently supported by the strategic deployment of crane systems in high-volume workflows.