Customized Applications

Innovative Customized Applications in Tennessee

Custom Applications That Move Your Business Forward

Tennessee’s industrial backbone is built on smart, scalable systems—and we’re here to support it. Our custom equipment applications are designed to meet your most specific material handling challenges, whether you're rotating oversized parts, managing work-in-process flow, or creating secure storage solutions. We work directly with you to develop systems that improve safety, speed, and space usage across your warehouse or factory. Built in Tennessee, built for you.

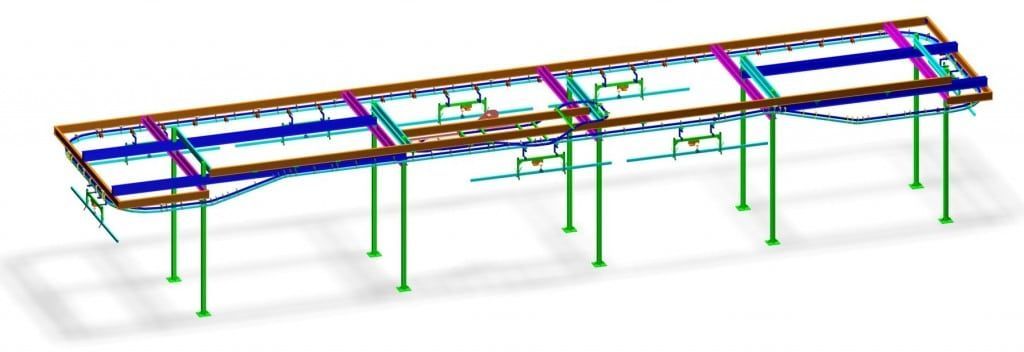

Overhead Fabric Assembly Work-in-Process Delivery System

The customer needed a system to handle large and bulky tents in a manufacturing process. The provided free-standing overhead monorail system with customized load lifters and carriers did just what the customer needed.

The implemented system helped to reduce the direct and indirect labor content and the production time significantly. Implementation of this system reduced direct and indirect labor content by over 60%, and productive throughput increased by 150%. This solution is one of many customized applications designed to meet specific material handling challenges in manufacturing environments.

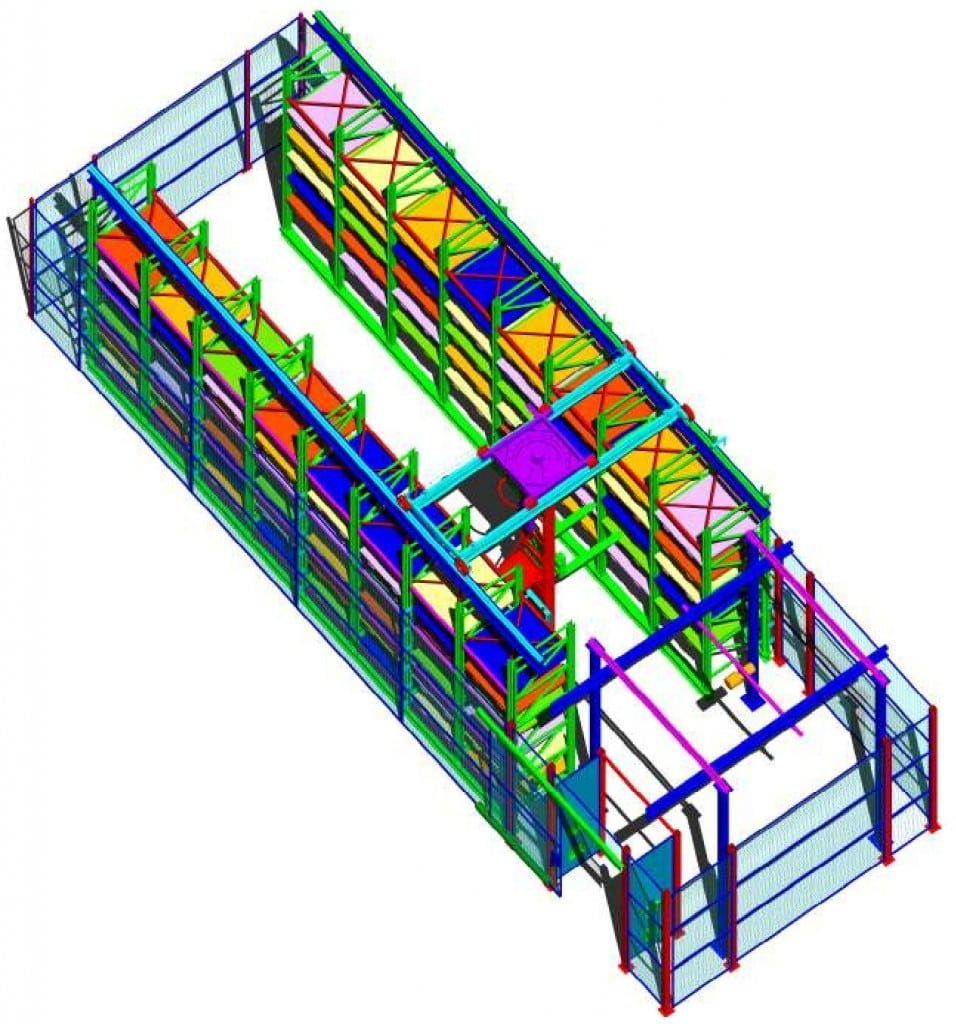

Crane Based Secure Die Storage System

The end customer was in need of a centralized die storage system to better manage the inventory of dies used within their production processes. To make sure that the movement of dies from the storage system was accurately tracked, a security enclosure was installed around the storage system as well as a radio tracking inventory system that monitored the RF chips installed in all die halves.

An associate had to provide a job number for RF chips installed in all die halves. An associate had to provide a job number and a die set to the storage system. Additionally, a Gorbel crane was installed to assist in moving the dies from the storage pallets to the transportation carts.

This type of solution is part of a broader range of customized applications aimed at improving traceability, security, and operational efficiency in high-value manufacturing environments.

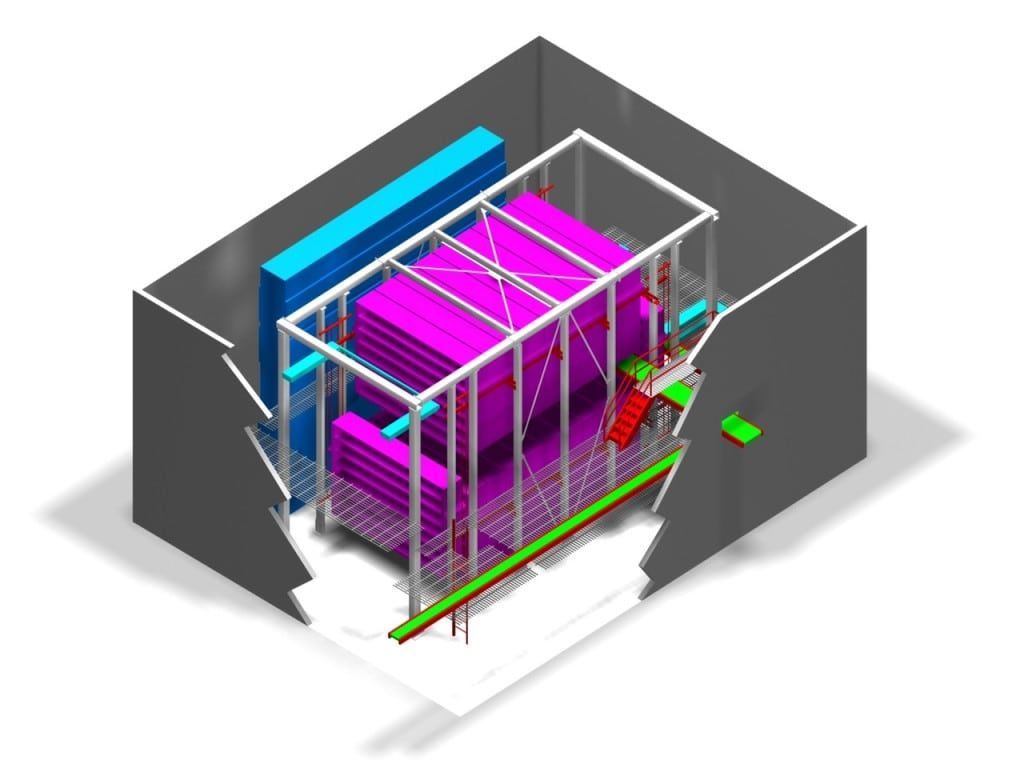

Continuous Flow Freezing System

The customer wanted to find a way to freeze products that eliminated the palletizing, depalletizing, and repalletizing typically found with most blast freezing operations for case goods.

The new system provides that capability through a carousel-based accumulation and conveyance process, with significantly increased product freeze and throughput rates as an additional benefit. In turn, the system minimized the non-value-added labor content by over 60%. Similar customized applications are being adopted across the industry to streamline cold chain logistics and reduce manual handling.

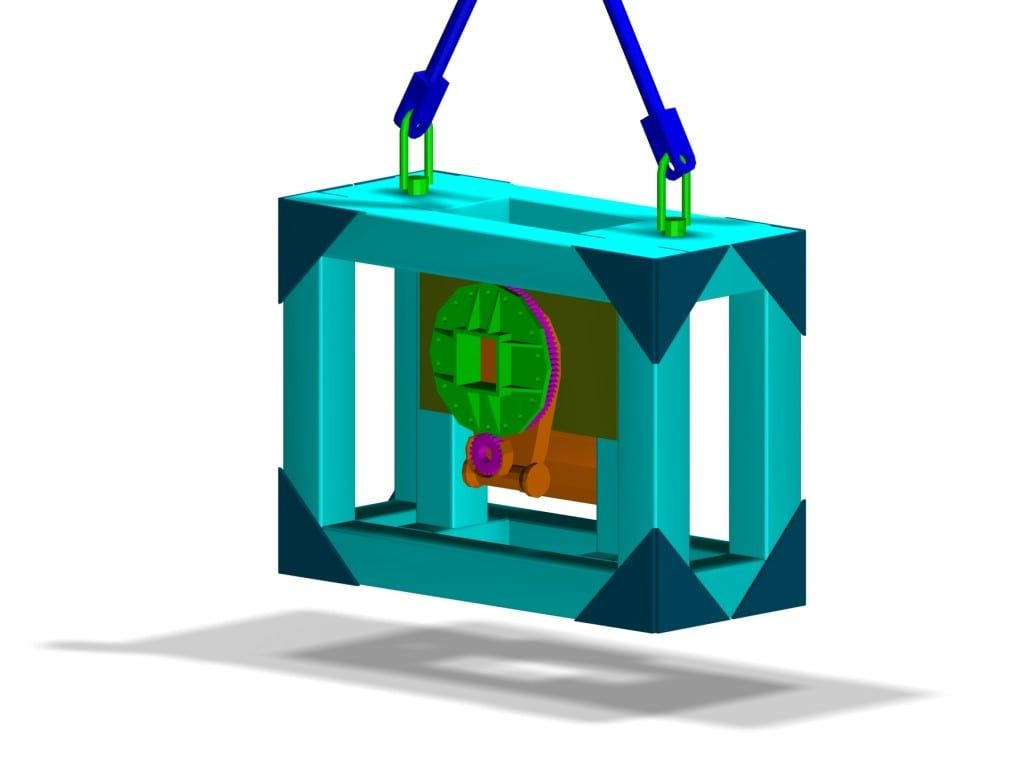

Crane Supported Large Part Rotation Device

The rotation tool allows the controlled rotation of a heavy production mold or tool suspended by two opposing points along the product’s rotation center line. The rotation tool works in pairs for safety with moderate to high tonnage loads. Lighter loads can be rotated with a single drive and idler support combination.

These solutions represent customized applications developed specifically to address safe and efficient handling of complex tooling in high-volume manufacturing.

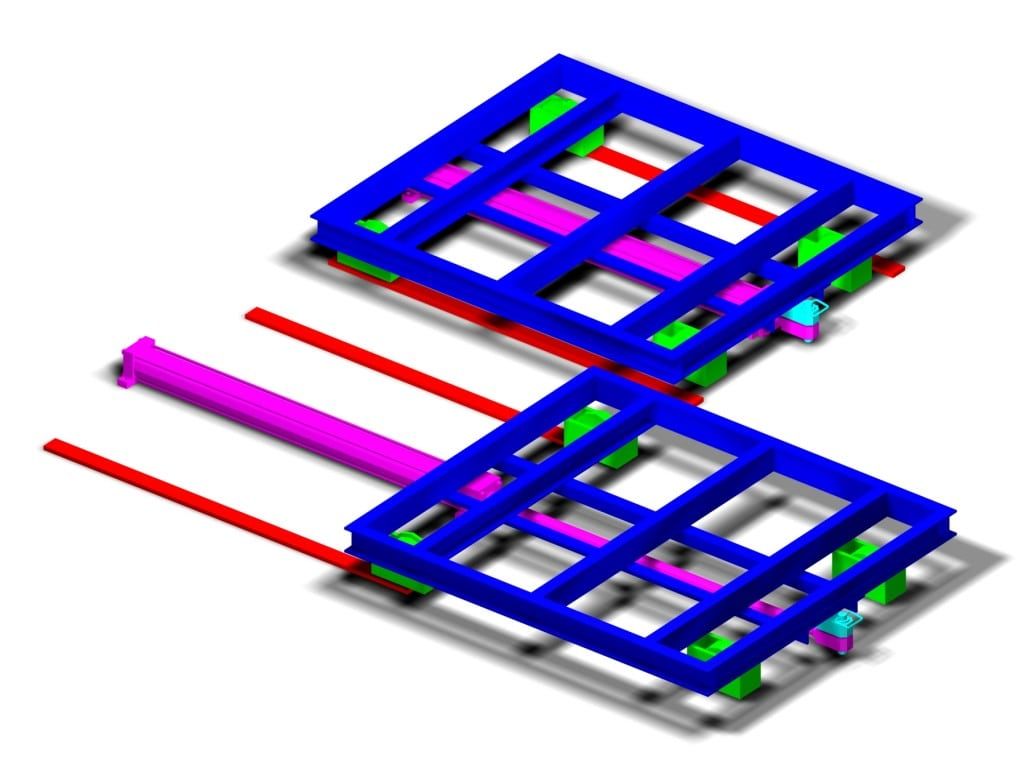

Heavy Part Order Picking Master Container Presentation Cell

A kitting operation was experiencing a number of associate ergonomic injuries as heavy packages were picked off floor-level pallets beneath traditional selective rack. The lift assist tools shown pneumatically move the bottom level load out into the picking aisle and back beneath the racks.

The associate does the picking with the load out in the picking aisle, resulting in less bending and stooping than currently seen. The cases picked per hour rate increases, and the associate's ergonomic environment is significantly improved. Many of these improvements stem from customized applications designed to reduce strain and enhance productivity in manual handling operations.