High-Density Systems

High-Density Solutions for High-Performance Facilities

In today’s fast-paced logistics and food industries, efficiency is everything. Our high-density systems are designed to maximize space, streamline storage, and boost productivity—even in the most demanding environments. Whether you're managing frozen goods or complex order picking workflows, our custom solutions bring clarity and control to your operations. Built for resilience and speed, these systems adapt to your specific needs and operational demands. Let us help you take control of your facility with innovative design and engineering. Connect with us to discover how our high-density solutions can transform your operation.

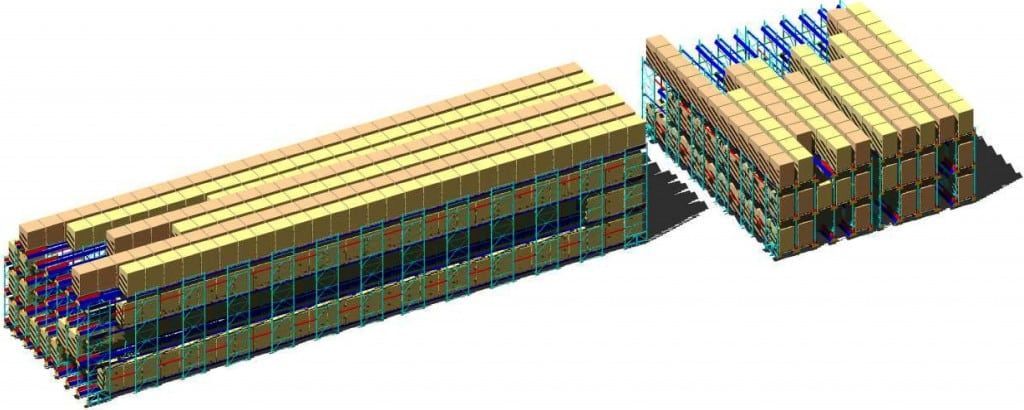

High-Density, High-Velocity Deep Lane Frozen Unit Load Product Accumulation & Order Picking System

A frozen food manufacturer needed to increase their product movement velocity and storage density in a new facility under consideration. The high-density rack system positions the customer’s high-velocity products closest to the shipping docks using a cart-based pallet handling method capable of dispensing 30–40 loads per hour to the forklift truck.

Additionally, the handling method limits the forklift truck activity to only the front or rear face of the storage structure. The system also positions the balance of the customer’s inventory around the high-velocity product in a push-back storage system again to provide higher storage density with good product velocity.

Many modern frozen storage facilities are leveraging high-density systems to achieve this blend of speed and space efficiency without sacrificing accessibility.

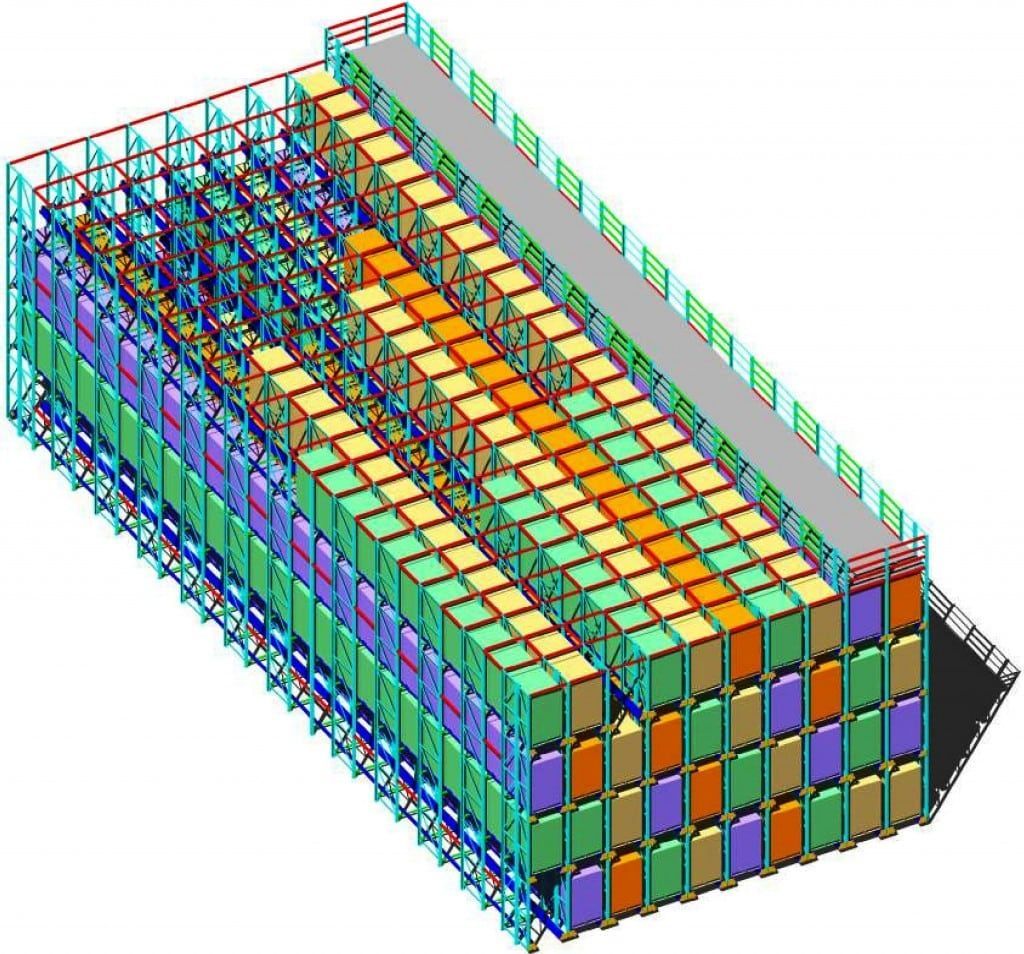

High-Density, High-Velocity Deep Lane Frozen Unit Load Product Accumulation and Order Picking System With Evaporator Access Mezzanine

A frozen food manufacturer needed to increase their product movement velocity and storage density in a new facility under consideration to allow 24/7 production capability but limit shipping to M-F operations. The cart-based (high density) storage system provides substantial cube density in a very small footprint while also providing easy maintenance access to the ceiling-supported evaporators.

Similar high-density systems are enabling facilities to decouple production from shipping schedules without needing massive building expansions.

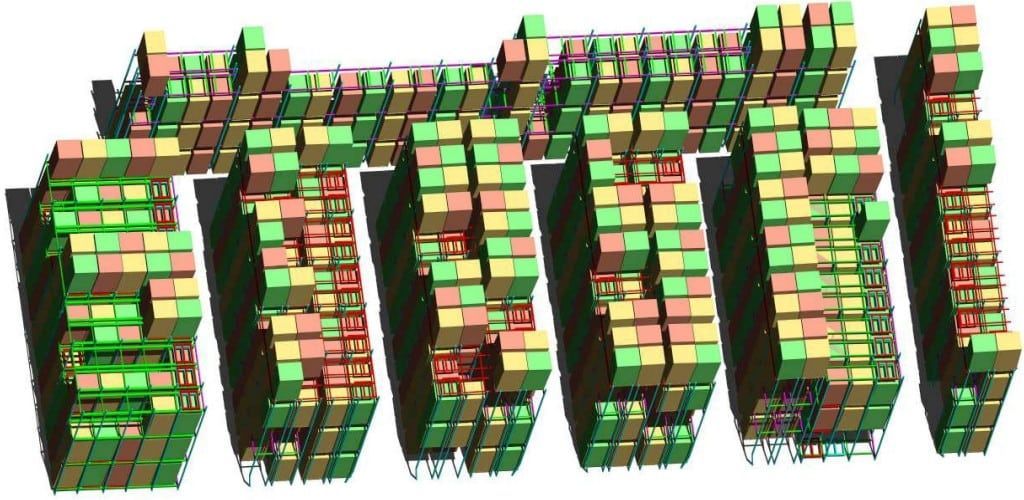

Double Deep & Push Back Narrow Aisle Frozen Product Storage System

The customer needed to maximize the storage capacity of finished products in their new freezer addition. The provided system utilized single-deep, double-deep, and push-back racking products to get the maximum number of pallets stored in the new freezer.

High-Volume Bottling Plant

A high-volume bottling plant needed to provide for the fast accumulation of pallet loads of product coming off of two bottling lines and also pre-stage several truck loads of outbound products near the shipping docks.

The high-density system developed provided accumulation positions for 960 loads adjacent to the palletizing process and 390 loads for the outbound shipment staging. It also doubled the number of loads stored in push-back racks in the same space. The configuration also made the removal of loads off the palletizer a one-man operation versus the 2-3 required before.

These types of high-density systems are becoming increasingly vital for manufacturers looking to streamline labor and optimize real-time inventory staging.

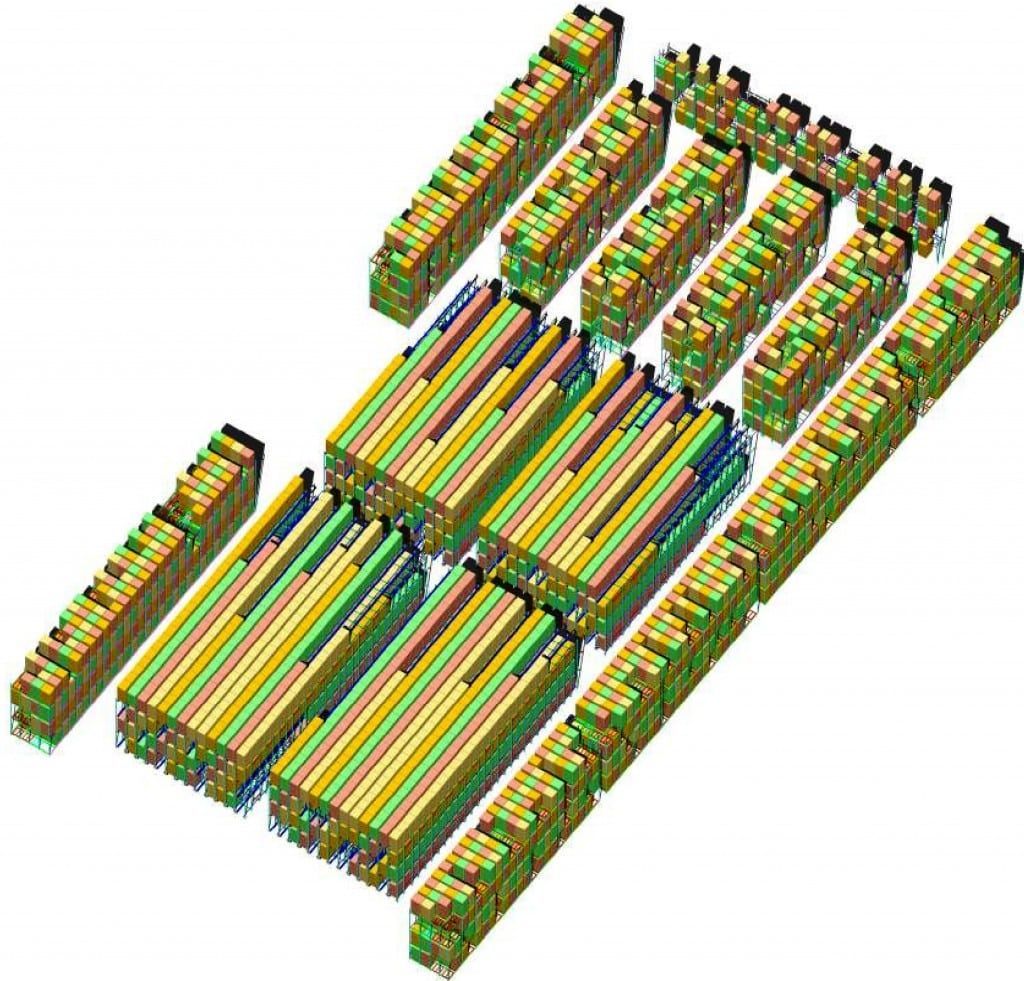

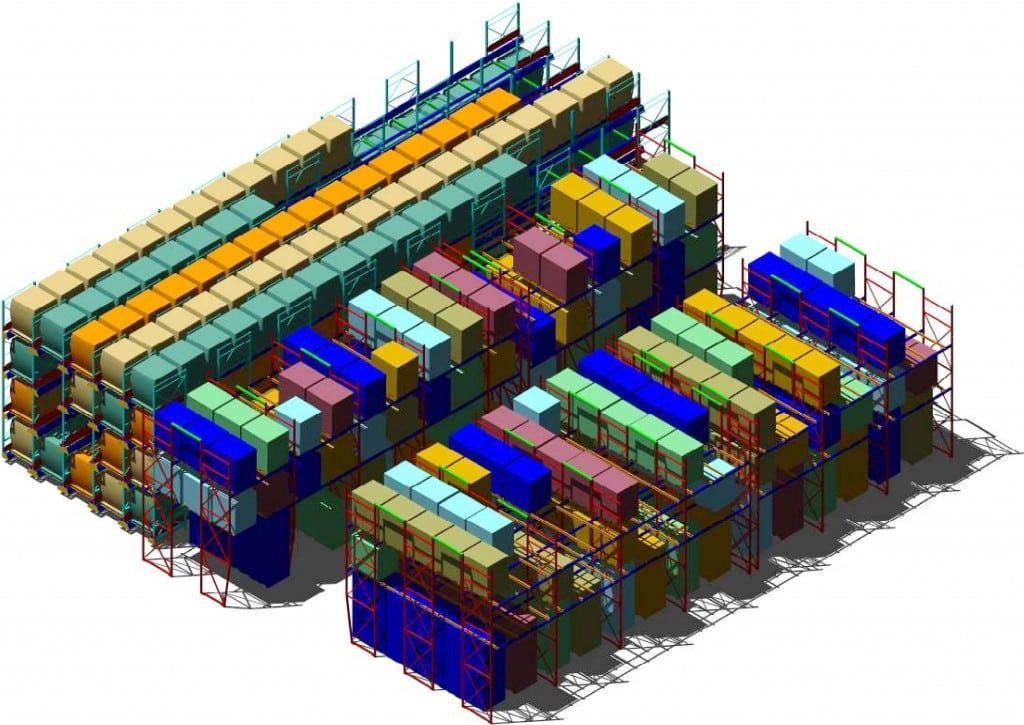

Blended High-Density Storage

The customer wanted to optimize the cube utilization of their inbound materials warehouse. There was a wide disparity of products with a wide variety of throughput across those inventories. By blending cart-based (high density system), push-back rack, and selective rack storage systems, the customer was able to increase the cube utilization by over 100%. At the same time, the number of times a pallet load of product was touched was significantly reduced.

Many distribution centers use this hybrid approach when deploying high-density systems to accommodate diverse inventory profiles while minimizing handling.

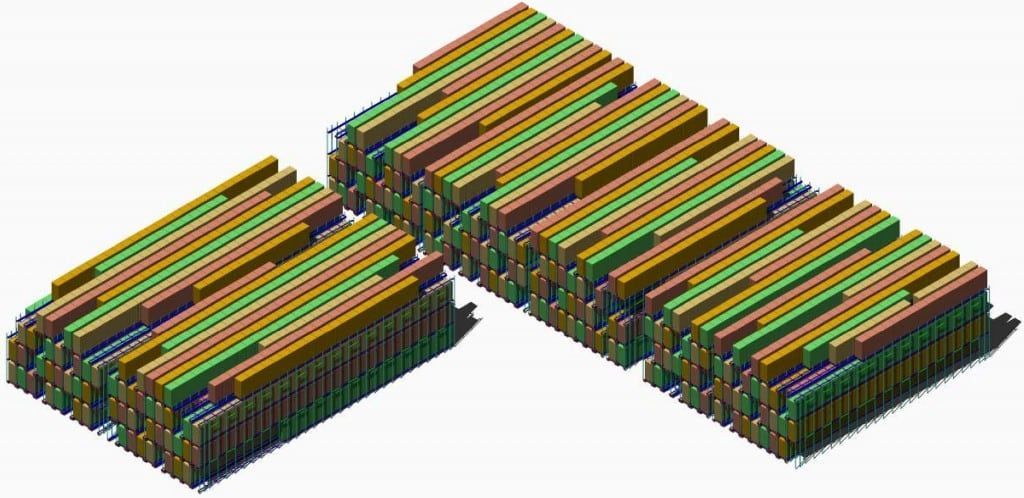

High-Density, High-Velocity Deep Lane Frozen Unit Load Product Accumulation & Order Picking System

A high-volume frozen food manufacturer needed substantial cube utilization improvements along with improved load throughput. A cart based (high density system) storage system was designed and installed that provided both of these requirements while at the same time keeping the distribution operation’s staffing levels the same.

The new system allowed the customer to retrieve all their inventory managed by third-party logistics companies back to the plant DC and place it fully under their control. The new freezer and cart-based high density storage system had a short payback compared to the customer’s initial ROI expectation.

Projects like this demonstrate how high-density systems can consolidate control, reduce external logistics costs, and accelerate return on investment.